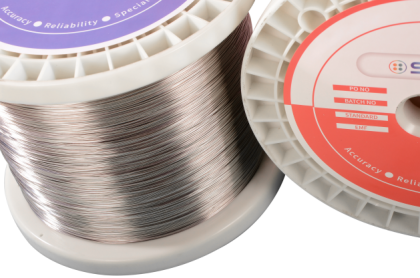

As a premier Chinese manufacturer and exporter of thermocouple solutions, we understand that global sourcing teams and engineers prioritize accuracy, durability, and technical clarity when selecting temperature sensors. Thermocouples are the backbone of industrial temperature measurement, trusted for their simplicity and reliability in extreme conditions.

Thermoelectric Effect:

Thermocouples operate based on the thermoelectric effect, where a temperature gradient between two dissimilar metals generates a voltage proportional to the temperature difference. This phenomenon forms the foundation of temperature measurement in thermocouples.

Principle of Seebeck Effect:

The Seebeck effect, a fundamental principle in thermocouple technology, states that when two different metals are brought together at their ends to form a junction, an electromotive force (EMF) is generated when there is a temperature gradient across the junction. This EMF is directly related to the temperature difference.

Measurement of EMF:

Thermocouples measure the EMF generated at the junction to determine the temperature at that point. By comparing this EMF to reference tables or calibration curves specific to the thermocouple type, the corresponding temperature can be accurately calculated.

Thermocouples are categorized by their metal alloys, each optimized for specific temperature ranges and environments such as:

|

Type

|

Materials

|

Temperature Range

|

Key Applications

|

|

K

|

Chromel (Ni-Cr) vs. Alumel (Ni-Al)

|

-200°C to +1260°C (-328°F to +2300°F)

|

General-purpose (furnaces, HVAC)

|

|

J

|

Iron vs. Constantan

|

-40°C to +750°C (-40°F to +1382°F)

|

Low-cost, oxidizing environments

|

|

T

|

Copper vs. Constantan

|

-200°C to +350°C (-328°F to +662°F)

|

Cryogenics, food processing

|

|

S/R/B

|

Pt-Rhodium vs. Platinum

|

0°C to 1600°C (32°F to 2912°F)

|

Aerospace, glass manufacturing

|

The choice of thermocouple type directly affects measurement accuracy, life, and cost efficiency.

Why Thermocouples Dominate Industrial Applications

A. Extreme Temperature Resilience

Operate in ranges from -270°C to 2300°C (-454°F to 4172°F), outperforming most RTDs and thermistors.

Noble metal types (S/R/B) are resistant to oxidizing atmospheres and molten metals.

Rapid Response Times

Ungrounded or grounded junctions allow response times as fast as 0.1 seconds in gas or liquid flows.

C. Cost-Effective Durability

No external power required; simple construction reduces failure points.

Mineral-insulated (MI) designs resist vibration, moisture, and chemical corrosion.

Advantages of Partnering with a Chinese Thermocouple Supplier

As a trusted exporter, we deliver:

A. Precision Engineering

ISO 9001-Certified Production: Strict quality control from raw materials to finished probes.

Custom Designs: Customize sheath materials, junction types, and connectors for your equipment.

B. Rapid Prototyping and Scalability

Flexible MOQs and JIT delivery for bulk orders.

C. Global Compliance and Support

Pre-certified for international standards (IEC 60584, ASTM E230).

24/7 multilingual technical support to help with integration and troubleshooting.

Understanding how thermocouples measure temperature is key to selecting the right sensor for your application. SICC combines cutting-edge technology with competitive pricing to deliver solutions that meet global standards.

IPv6 network supported

IPv6 network supported