02/2023.03

How is Mineral insulated cable made ?

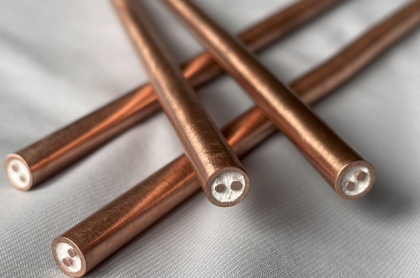

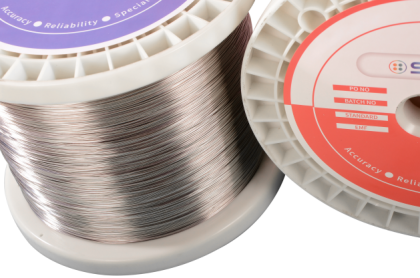

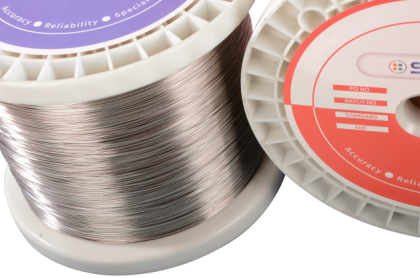

Mineral insulated thermocouple cable is used to insulate Thermocouple wires from one another and from the metal sheath that surrounds them. The MIMS cable has two or four Thermocouple wires running down the middle of the tube, the tube is then filled with magnesium oxide powder and compacted to ensure the wires are properly insulated and separated. It has some advantages: first, the response time is fast, the minimum number of milliseconds can be reached, which is suitable for the detection of microcomputer control; second, the chemical stability is good and the deviation of the indexing drift is small after using for a long time, thus due to long life; third, the mechanical properties is good which can withstand strong vibration and impact; fourth, the high pressure resistance is greater than 3000MPa; fifth, the insulation properties is good under high temperature conditions; sixth, it is suitable for measuring temperature and automatically controlling temperature under the condition of high pressure, high temperature at the same time; seventh, it can be bent freely with small outer diameter, suitable for complex, narrow bending, miniaturized occasions to measure and control temperature; therefore, Mineral insulated cable has been widely used. The manufacturing process of Mineral insulated cable is combined the Bare thermocouple wire, insulating material (generally magnesium oxide powder) and sheath tube to form a solid body. After the assembly, the drawing machine is used (chain puller and cylinder puller) toreducethe diameter gradually from the maximum diameter of 23mm to 8mm and the minimum diameter is reduced to 0.25mm. During each diameter reduction process, the metal is compressed and deformed, a deformation stress is generated, the Mineral insulated cable will be broken if the deformation stress is not eliminated. In order to eliminate the deformation stress, it is necessary to anneal in a heat treatment furnace to restore the metallographic structure, and the reduction process is continued until the desired outer diameter is reached. Since the requirement of material accuracy is very strict,currently we imply box furnace, the belt type annealing furnace or the short circuit annealing. But the results does not reach the stability process requirement, so the high grade cable can not be come out. We provide a method for manufacturing Mineral insulated thermocouple cable with gas shield to achieve the goal of high quality and low production cost. The Thermocouple wire is inserted into the prefabricated hole of the insulated material and the metal sleeve is sleeved on the outside of the insulating material, its diameter is reduced and heat treated to reach the outer diameter meeting the requirement. The Thermocouple material is heated and cooled equally, uniformly, so that the entire wires can be reached to data requirements by continuous heat treatment. By gas protection and continuous heat treatment, the qualified product rate is above 70%,...

Read More

IPv6 network supported

IPv6 network supported