Thermocouple is one kind of temperature-sensing element by measuring EMF. It is made by welding two different metal materials at one end. The unsoldered end is called the reference end and the soldered end is called the measurement end, the welding quality of the measuring end directly affects the reliability of temperature measurement. Therefore, it is required that the measuring end is welded firmly, with metallic luster, smooth surface, no contamination, deterioration, slag inclusion and cracks. In order to reduce heat transfer errors and dynamic errors, the size of the solder joint should be as small as possible, usually twice the diameter of the thermocouple.

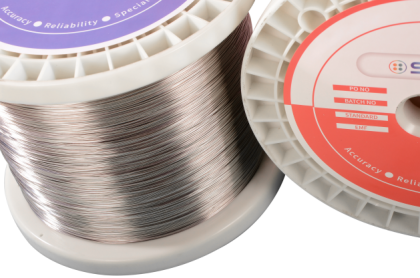

Before welding, the top of the electrode to be welded should be twisted into a twist as shown in Figure 1 or the two tops should be aligned.

Figure 1

1. Gas welding

Twist the top of the thermode into the form shown in Figure 1, heat it slightly and dip it in flux, then use an acetylene flame to melt the measuring end into a ball, quickly remove the measuring end from the flame and put it into hot water.

2. Arc welding

Arc welding uses a high temperature arc to melt the measuring end of a thermocouple into a spherical shape. Commonly used are AC arc welding and DC arc welding. AC arc welding is generally used to weld base metal thermocouple. Before welding, the top of the hot electrode should also be dipped in flux. After welding, the flux on the solder joint should be removed. DC arc welding is generally used to weld noble metal thermocouple.

3. Butt welding

Align the thermode tips with a little pressure and turn on the power to fuse the contact surfaces together. This welding method is more convenient.

4. DC argon arc welding

Usually, the DC argon arc welding machine is protected by argon gas, with high-frequency arc ignition, DC welding and can perform butt welding. It is composed of power supply, DC welding power supply, welding torch, high frequency oscillator, butt welding power supply and fixture. The characteristics of this welding device are easy to use, fast welding speed, no staining, no air holes, bright and fine welding ends, and can be used for multiple purposes. It can weld various metal materials and various thermocouple of different specifications.

5. Salt Bath Soldering

The welding device consists of a voltage regulator (3-5KW), graphite crucible and welding clips. The crucible acts as a power source - the electrode is welded to the hot electrode as the other electrode. Before welding, clean the oxide on the surface of the hot electrode to be welded and twist it into a twist shape. Put the carbon rod on the barium chloride and turn on the power to melt the barium chloride. After touching the arc, leave quickly and wash the barium chloride particles on the measuring end and hot electrode with hot water.

Related products: nickel chrome wire,copper nickel wire.

IPv6 network supported

IPv6 network supported