1.Use other types of wires instead of compensation thermocouple wires

According to the

operation principle of thermocouple temperature measurement, the thermoelectric

potential of the thermocouple circuit is related to the measured temperature

and the temperature of the thermocouple reference end. In the industrial site,

the temperature of the thermocouple reference end is unstable and will be

influenced by its surrounding environment. With temperature fluctuation ofthe

reference end, the compensating wire is used to extend the

reference end to an environment with stable temperature or simply somewhere

away from the heat source to compensate the deviation caused by temperature

changeat the reference end.Other types of wires can

transmit the mV signal value generated by thermocouple temperature measurement,

but can not compensate the temperature of the thermocouple reference end, which

might result in inaccurate temperature compensation of thermocouple temperature

measurement system.

Correct method:For thermocouple signal transmission, we must use the

matching type of thermocouple compensating wires with the thermocouple , it is

prohibited to replace the compensating wire with a normal electric wire.

2.The insulation layer of the thermocouple compensating wire is damaged.

While connecting

the thermocouple, there might be certain degree of wear on the insulation layer

at the outlet of the thermocouple junction box or at other parts of the

compensating wire. As a result, the temperature display value on the display

instrument or in the DCS system is generally smaller than usual.

Correct method:Make sure to fix the insulation layer after finding

damaged parts on the thermocouple compensating wire, and restore the normal

display value of the control instrument or the paperless temperature recorder.

3.The measurement error occurs when the positive and negative polarity of the

thermocouple compensating wire is connected reversely.

The thermocouple

as well as the thermocouple compensating wire both have positive and negative

polarity.When the compensating wire is inversely connected, the display

value on the paperless temperature recording instrument changes greatly as

follows:

A. After

inversely connecting the polarity of the compensating wire, when the

temperature at the junction of the thermocouple and the compensating wire is

higher than the temperature in the control room, the temperatureshowedon the instrument will be lower than the actual measured temperature.

B. After

inversely connecting the polarity of the compensating wires, when the

temperature at the junction of the thermocouple and the compensating wire is lower

than the temperature in the control room, the temperatureshowedon the instrument will be higher than the actual measured temperature.

C. After

inversely connecting the polarity of the compensating wires, when the

temperature at the junction of the thermocouple and the compensating wire is

the same as the temperature in the control room, the temperatureshowedon the instrument will be the same as the actual measured temperature.

It is proved by

theory that the error caused by the reverse connection of the polarity of the thermocouple

compensating wire is about twice more than that when no compensating wire is

used.

Different types

of thermocouple compensating wires all have red insulation layer for the

positive polarity, but different colors for the negative polarity. As a result,

the type of compensating wires can be distinguished according to the color of the

insulation layer.

Correct method:Correctly distinguish the positive and the negative

polarity of the thermocouple as well as the thermocouple compensating wire, the

polarity can not be connected reversely.

4. Poor contact between the thermocouple compensating wire and the wiring

terminal

The thermocouple

compensating wire is relatively hard, so it is easy to have poor contact

between the wire and the wiring terminal when connecting or using it. There

might be no display value on the DCS system, or the display value might exceed

the range of the instrument measurement.

Correct method:Tighten up the wiring terminal and eliminate the poor

contact to restore the normal measurement display of the instrument.

5.The joint in the thermocouple compensating wire has poor contact

When producing

the thermocouple compensating wire, the number of joints per unit length is

limited by standards for the manufacturer. When the extension is needed in the

process of laying the compensating wire for long distance, the technician

commonly connects the joints of compensating wires together and then apply the

insulation on it directly. After using it for a period of time,inaccurate

measurement as well as increases the occurrence of deviation.

Correct method:if it is necessary to extend the length of the

compensating wire, connect the same polarity of the same type of compensating

wires together, weld firmly the connection point, and finally put it into use

after applying the insulation.

6.The signal will be interfered when the compensating wire is laid in

parallel with the power cable

An enterprise

laid thermocouple compensating wires and electrical power cables in the same

cable bridge during the construction. When the system was put into use, the DCS

system showed the thermocouple temperature rose and dropped unstably. After

careful inspection, it is confirmed that the thermocouple measurement signal is

interfered by the power line which caused the temperature measurement deviation

of 100℃.

Correct method:During the construction, lay the thermocouple

compensating wire and the power cable in the same direction, but lay the power

bridge and the signal instrument bridge separately with shielded compensating

wires. If the compensating wire has to be on the same bridge with the power

cable, shielding baffles or cross-laying method should be used inside the

bridge frame to minimize the interference of thermocouple signals.

7. Using the thermocouple compensating wire for long distance, measurement

errors might occur due to the signal attenuation and the interference

The electric

potential value generated during thermocouple temperature measurement is mV

signal. Due to the increase of the length of the compensating wire, the signal

attenuation and the on-site magneto-electric interference mix together, which

makes the temperature display value of the instrument or the DCS system

fluctuate.

Solution:

A. When laying

compensating wires for long distance is needed, the compensating wire’s

diameter should not be less than Φ1.5mm2 which can reduce the attenuation of

the mV signal.

B. Pick up the

shielded compensating wire and ground the shielding layer according to the

standard (the shielding layer must be grounded at the end of the compensating

wire, and the grounded layer should be incorporated into the grounding network

of the instrument signal, and the grounded layer should not be incorporated

into the electrical grounding network of the factory). This can avoid

measurement errors caused by incorrect method of grounding for the shielding

layer.

C. Use a

temperature transmitter to convert local thermocouple signal into the 4-20ma

signal in order to improve the anti-interference ability of the signal.

8. After using a temperature transmitter along with the thermocouple, the

compensating wire is not needed.

The thermocouple

temperature transmitter is usually installed in the thermocouple junction box

and the control cabinet, which are two different types of the temperature

transmitter:

A. The

temperature transmitter installed in the thermocouple junction box forms an

integrated thermocouple temperature transmitter. The thermocouple wires are

directly connected to the input end of the temperature transmitter, and the

output uses 2-wire system of 4-20mA signal. The transmitter is directly

connected to the display instrument or the DCS system with twisted pair cables

or two core shielded cable, without thermocouple compensating wires.

B. If the

temperature transmitter is installed in the control cabinet, the thermocouple

and the temperature transmitter must be connected with compensation wire. The

transmitter and the display instrument or DCS system shall be directly

connected with the twisted pair or the

two-core shielded cable, and the thermocouple compensating wire is not used in

this case.

Correct method: Based on the application scenario, we determine whether

the compensating wire needs to be used for the thermocouple temperature

transmission. A compensating wire must be used to connect the thermocouple and

the guide rail type of the temperature transmitter.

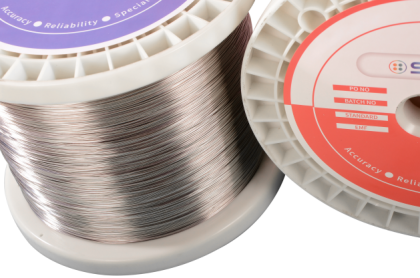

SICC provides various bare thermocouple wire,Type K,J,T,E,N thermocouple wire,extension thermocouple wire,get details from us quickly.

IPv6 network supported

IPv6 network supported