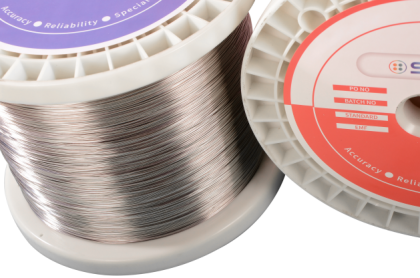

The problem of accuracy deviations on the same batch of Mineral insulated thermocouple cable

December 29, 2023

The problem of accuracy deviations between suppliers and customers on the same batch of Mineral insulated thermocouple cable can occur due to various reasons. Here are some potential causes and suggestions to address this issue:

1.Calibration discrepancies: Suppliers and customers may use different calibration methods or equipment for Mineral insulated thermocouple cable , leading to variations in the measured accuracy. It is essential to ensure that both parties follow standardized calibration procedures and use traceable calibration equipment to minimize deviations. Regular calibration checks and traceability to national or international standards can help maintain consistency for Mineral insulated thermocouple cable.

2.Measurement equipment differences: Suppliers and customers may use different types or models of measurement equipment, which can have variations in accuracy and calibration. It is crucial to specify the required measurement equipment and ensure both parties use the same or equivalent instruments to achieve consistent results. This includes considering factors such as measurement resolution, measurement uncertainty, and calibration traceability for Mineral insulated thermocouple cable.

3.Environmental conditions: Different environmental conditions during testing Mineral insulated thermocouple cable can affect the accuracy of thermocouple measurements. Factors such as temperature, humidity, and electromagnetic interference can introduce deviations. It is important to establish and agree upon standardized environmental conditions for testing to minimize variations. Specifications for temperature stabilization, shielding, and adequate grounding can help reduce environmental influences to Mineral insulated thermocouple cable.

4.Manufacturing process variations: Even within the same batch of Mineral insulated thermocouple cables, there can be minor manufacturing process variations that affect accuracy. Factors such as powder compaction, insulation thickness, and wire alignment can contribute to measurement discrepancies. Regular quality control checks and adherence to manufacturing standards can help minimize process variations.

To address accuracy deviations of Mineral insulated thermocouple cable, it is recommended for suppliers and customers to collaborate closely and establish clear communication channels. This includes sharing calibration certificates, measurement protocols, and any relevant documentation to ensure transparency and alignment. Consider conducting joint testing or interlaboratory comparisons to identify and rectify any discrepancies.The two parties conduct multiple data comparisons to find out the differences in their test data and reduce the relative accuracy difference.

If you need any help about Mineral insulated thermocouple cable, pls feel free to contact us!

IPv6 network supported

IPv6 network supported