Basic models and parameters of Shock Resistant Pressure Gauge

|

Model

|

Structure

|

Scale range

|

Accuracy level

|

|

YN-60

|

Radial

|

0~0.1;0~0.16;0~0.25;0~0.4:

0~0.6;0~1;0~1 6;0~2.5;0~4

0~6;0~10~;0~16;0~25

|

2.5

|

|

YN-60ZT

|

Axial edge

|

|

YN-60B

|

Radial

|

|

YN-63B

|

Axial edge

|

|

YN-100

|

Radial

|

0~0.1;0~0.16;0~0.25;0~0.4;

0~0.6;0-1;0~1.6;0~2.5;0~4;

0~6;0~1 0;0~1 6;0~25;0~40;

0~60

|

1.5

|

|

YN-100ZT

|

Axial edge

|

|

YN-100B

|

Radial

|

|

YN-103B

|

Axial edge

|

|

YN-150

|

Radial

|

0~0.1;0~0 1 6;0~0.25;0~0.4;

0~0.6;0~1;0~1.6;0~2.5;0~4;

0~6;0~10;0~16;0~25;0~40;

0~60;0~100

|

|

YN-150ZT

|

Axial edge

|

|

YN-150B

|

Radial

|

|

YN-153B

|

Axial edge

|

|

|

|

|

|

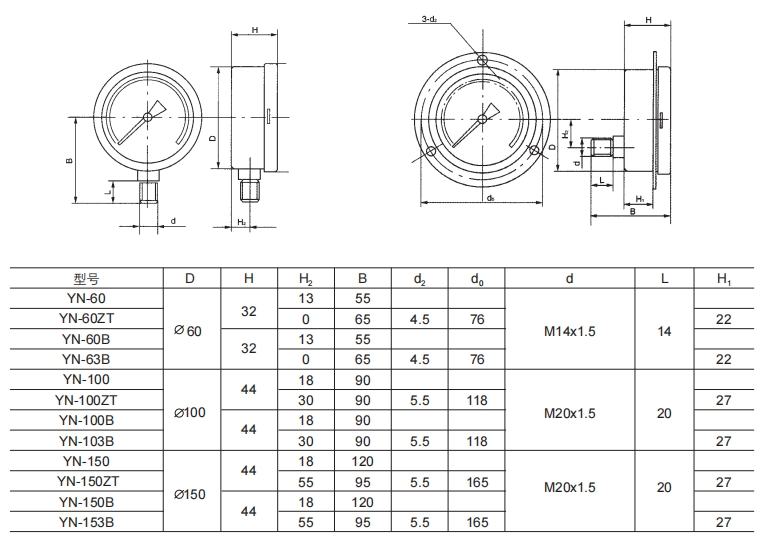

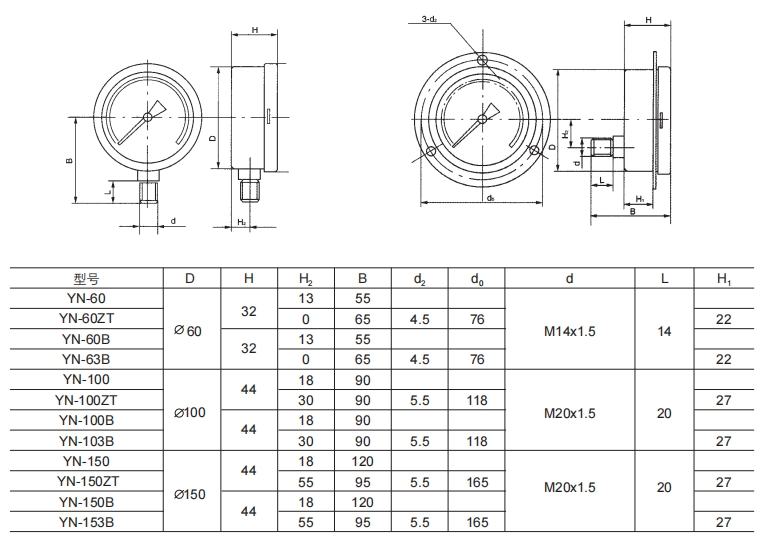

Dimensions of Shock Resistant Pressure Gauge

Excellent Vibration Resistance

The internal filling is filled with a high-viscosity damping fluid (such as silicone oil), which effectively absorbs mechanical vibration energy and significantly reduces pointer fluctuation. Compared to ordinary pressure gauges, pointer fluctuation can be reduced by over 80% under the same vibration environment.

The reinforced structural design, with shock-resistant materials used in both the case and movement, reduces vibration transmission and ensures stable operation in high-vibration environments.

Accurate Readings and Stability

The damping fluid provides a smooth pointer movement, preventing misinterpretations caused by transient pressure fluctuations. It maintains a high accuracy of ±1.6% over a long period of time, making it suitable for pulsating pressure applications such as compressors, pumps, and diesel engines.

The fully sealed structure provides a high level of protection and operates in harsh environments such as dust, underwater, and high humidity. Its anti-clogging design supports measurement of high-viscosity, easily solidifying media such as mud and cement.

Extended Service Life

Effectively reducing wear on components like gears and hairsprings,Shock Resistant Pressure Gauges can extend their service life by 2-3 times compared to conventional pressure gauges, reducing maintenance costs and the risk of accidents.

Authoritative Certification: Our production systems and products are fully ISO 9001:2015 certified. Select models carry ATEX or IECEx explosion-proof certification for use in explosive environments.

Guaranteed Accuracy: Standard Shock Resistant Pressure Gauges offer an accuracy of ±1.0% of F.S., calibrated by a CNAS-accredited laboratory with a traceable calibration certificate.

Superior Quality: We guarantee that our Shock Resistant Pressure Gauges have a mean time between failures (MTBF) far exceeding the industry average, demonstrating our confidence in their design and manufacturing quality.

We sincerely invite you to contact us and let us provide you with a stable and reliable Shock Resistant Pressure Gauge for your equipment and systems with our professional products and solutions!

IPv6 network supported

IPv6 network supported