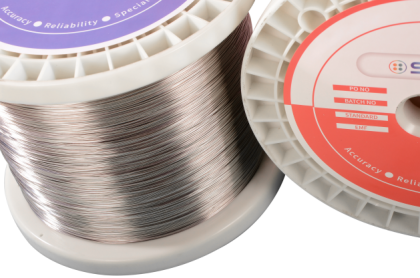

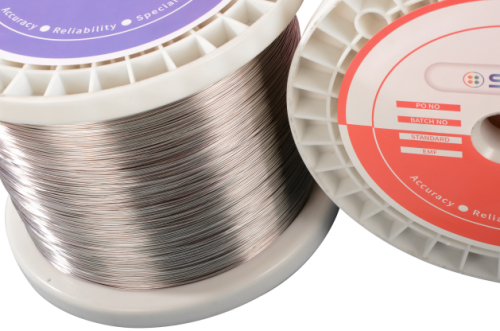

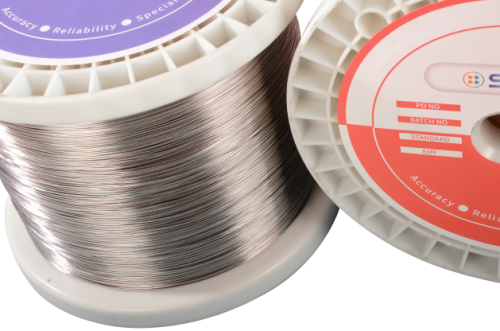

In terms of manufacturing technology, we use advanced multi-process precision processing technology. Starting from the selection of raw materials, we ensure that the purity of each element of the Type D thermocouple alloy wire meets high chemical requirements, and then go through complex processes such as smelting and drawing. During the smelting process, parameters such as temperature, pressure and time are strictly controlled to ensure the uniformity of the thermocouple wire alloy composition; the drawing process gradually processes the rough blank into fine wires that meet different specifications, and in this process, the surface quality of the wire is strictly controlled to ensure its smoothness and straightness, reducing signal interference and errors during use.

Precision and reliability are the important advantages of our Type D thermocouple wire. After a strict calibration and quality inspection system, its thermoelectric potential accuracy is extremely high, which can meet the application scenarios with demanding requirements on temperature measurement accuracy. Whether it is static high-temperature environment monitoring or dynamic measurement during temperature changes, it can provide stable and reliable data. In addition, our Type D thermocouple alloy wire has good corrosion resistance. It can still maintain good performance in an environment with high temperature, high humidity and possible chemical corrosive substances, which greatly extends the service life of the thermocouple.

Application cases in different industries:

Metallurgy and vacuum melting: Use Type D thermocouple wire when melting titanium alloy in electron beam furnace, the anti-electromagnetic interference ability is improved by 50% at 2500℃, the temperature control accuracy is ±1.5℃, and the alloy component segregation defect rate is reduced by 20%

Semiconductor industry: Use Type D thermocouple wire when annealing silicon carbide wafers. In a nitrogen atmosphere at 2200℃, 0.08mm ultra-fine alloy wire achieves ±0.5℃ temperature measurement accuracy, wafer edge temperature uniformity <1%, and chip yield is increased by 3%

Aerospace: Dynamic temperature measurement of rocket combustion chamber. In a hydrogen-oxygen combustion environment at 2400℃, 0.1mm diameter D-type thermocouple alloy wire achieves 1000Hz high-frequency sampling, capturing ±5℃ temperature oscillations that are missed by traditional sensors, helping to improve thrust vector control accuracy by 15%.

Choose our Type D thermocouple wire, you will get a high-quality temperature measurement solution to help improve your production efficiency and product quality.

Product competitiveness is enhanced:

Using our high-precision, high-temperature resistant Type D thermocouple wire, you can maintain excellent performance in high-temperature and complex environments, attracting more customers and increasing market share.

Cost and efficiency optimization:

Reduce raw material procurement costs, shorten production cycles, increase inventory turnover, and release working capital for R&D or market expansion.

Market expansion assistance

With the customization capabilities and cost , you can more smoothly enter markets with abundant requirements and expand its global business territory.

Feel free to contact us for more product information and technical consultation!

IPv6 network supported

IPv6 network supported