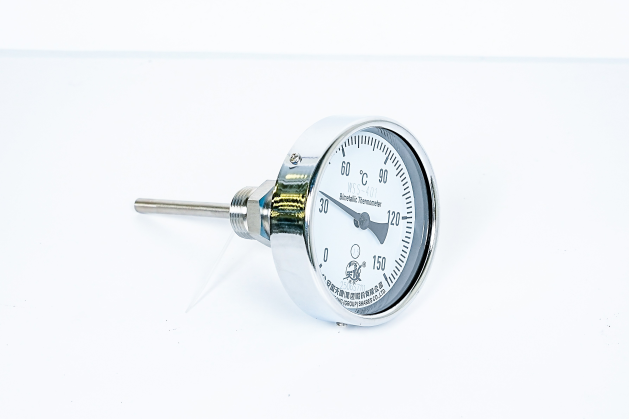

Structural Features of Axial Bimetallic Thermometer

The pointer dial is connected perpendicularly to the protection tube: The pointer dial and the protective tube are at a 90° angle, allowing readings on vertically mounted pipes or equipment.

Main components of Axial Bimetallic Thermometerinclude the temperature sensing element (bimetallic strip), protective tube, pointer shaft, case, dial, and pointer. The temperature sensing element is wound in a spiral shape, with one end fixed and the other end connected to the pointer shaft. This rotates the pointer as the temperature changes.

Measuring range: Typically -80°C to +500°C, with common scale ranges including 0-100°C, 0-200°C, and 0-300°C.

Accuracy levels: Generally available in 1.0 and 1.5 grades, with 1.5 being the most common in industry. For precision measurements, 0.5 or 0.25 grades are available.

Dial diameter: Common sizes are 60mm, 100mm, and 150mm. The larger the diameter, the clearer the reading.

Protection rating: Typically IP55 or IP65, meeting various environmental requirements.

Mounting options include movable external threads, fixed threads, compression threads, compression flanges, and fixed flanges, facilitating installation on various devices.

Key Selection Points of Bimetallic Thermometer

Determine the measurement range: Select the appropriate range based on actual temperature requirements.

Consider accuracy requirements: For industrial sites, generally choose Class 1.5; for precision measurements, choose Class 0.5 or 0.25.

Determine the mounting type: Choose axial, radial, or universal mounting depending on the equipment structure.

Focus on the protection level: For corrosive or humid environments, choose IP65 or higher.

Match the media characteristics: For corrosive media, choose 316L stainless steel protective tubes; for high-temperature media, choose higher-grade alloys such as the INC series.

Bimetallic Thermometer Model Reference:

|

Reference

|

Guide

|

|

WSS

|

Bimetallic thermometer

|

|

X

|

Electrical contact structure(optional)

|

|

P

|

Remote structure(optional)

|

|

N

|

Earthquake-resistant structure(optional)

|

|

Dial diameter

|

3(60mm)

|

4(100mm)

|

5(150mm)

|

|

|

|

|

|

Location

|

0(Axial)

|

1(Radial)

|

2(135°)

|

8(Universal)

|

|

|

|

|

Fixed Installation

|

0(No fixed)

|

1(Movable external thread)

|

2(Movable internal thread)

|

3(Fixed thread)

|

4(Fixed flange)

|

5(Ferrule thread)

|

6(Ferrule

flange)

|

Our Advantages of Axial Bimetallic thermometer

Expert Technical Support: Our team of engineers isglad to provide you with selection advice and solutions, not just a product salesperson.

Consistent Quality and Traceability: Every Axial Bimetallic Thermometer undergoes rigorous calibration and testing before shipment to ensure consistent performance. Key components are traceable.

Global Supply Chain Reliability: Our stable production capacity and efficient logistics support ensure timely and accurate delivery of your orders, making us your reliable extended warehouse.

Applications: Oil & Gas, Chemical & Pharmaceutical, Power & Energy, Food & Beverage, HVAC, and many other industries.

For more information or to discuss how our Axial Bimetallic thermometer can meet your specific needs, please reach out to us today.

We look forward to working with you to boost your production capabilities!

IPv6 network supported

IPv6 network supported